I grew up in the state of North Carolina, so whenever I hear a Southern accent, it brings back many fond memories. As so it was when I got on the phone with Leroy Walden, Vice President of McKenney’s, Inc. McKenney’s is a mechanical contractor in the Southeast that offers a full range of services, including heating, ventilating, and air conditioning (HVAC), process piping, plumbing, service and maintenance, and building automation and control systems. As Leroy tells the story, in early 2012, McKenney’s joined Gulf Power and Chevron Energy Solutions to implement a new energy management system at Eglin Air Force Base (Eglin). Eglin, at 724 square miles, is one of the largest military bases in the world, and includes hundreds of buildings and a base population of about 17,000.

We’ll use the five-layer framework, Things, Connect, Collect, Learn, Do (highlighted in the book Precision: Principles, Practices and Solutions for the Internet of Things), and for buildings, talk about the things, how they are connected, how data is collected, what is being learned, and finally what they are doing differently.

Things

Eglin has thousands of devices from disparate manufacturers and protocols, including a very large HVAC control system and wireless-power-metering infrastructure. In aggregate, there are 20,000 sensors and data inputs in more than 100 buildings.

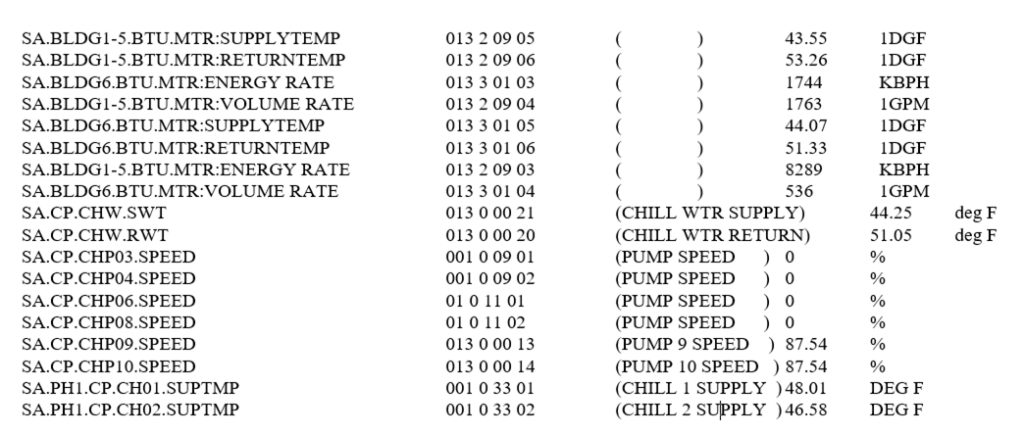

Figure 1. McQuay Chiller Data.

An example of one kind of machine is the McQuay Chiller. In air conditioning systems, chilled water is typically distributed to heat exchangers (or coils) in air-handling units or other types of terminal devices, which cools the air in the respective space(s); then the water is re-circulated back to the chiller to be cooled again. The chiller sensors continuously report on chilled-water-supply temperature, chilled-water-return temperature and flow status, logging in 15-minute intervals. An example of the kind of data is shown in Figure 1.

A variety of other sensors are also on the base, including the Sensus FlexNet electric meters, which continuously read power metrics (e.g., kVA and kVAh). The meters are deployed on outlying buildings that have no building automation. In addition, Schneider Electric’s room thermostat continuously provides space temperature and humidity and occupancy status, logged in 15-minute intervals.

Johnson Controls’ Variable Air Volume (VAV) controller continuously provides airflow, discharge-air temperature, damper position and heat-output readings, which are logged in 15-minute intervals. VAV is a type of HVAC system that, unlike constant air volume (CAV) systems—which supply a constant airflow at a variable temperature—vary the airflow at a constant temperature. The advantages of VAV systems over CAV systems include more precise temperature control, reduced compressor wear, lower energy consumption by system fans, reduced fan noise and additional passive dehumidification.

Connect

Eglin uses Tridium Niagara Framework to connect many of these machines. Tridium provides a multi-vendor interoperable control system that satisfies the need for Internet connectivity while maintaining the determinism and integrity required for real-time control. To be deterministic means that every time the same function occurs, it must happen in exactly the same way and at exactly the same speed.

For example, consider a building outfitted with a smart electrical meter that provides the current, real-time price of electricity being used and a chiller that controls the temperature. Independently, the electrical meter and the chiller cannot communicate; however, when joined together using a standard communications and applications infrastructure it becomes possible to vary the building temperature and thus vary chiller energy consumption in accordance with energy prices.

The key elements of the framework include database management, security, web server, browser-user interface, real-time control engine, enterprise support and a complete application-development environment. There is also a hardware component. The Java Application Control Engine (JACE) controllers are a series of embedded computer hardware devices that act in an area-controller capacity to distribute real-time-control functions across an Ethernet bus in a large system.

JACE connects three of widely used building connection protocols: BACnet, LonMark and Modbus. While all three have been used successfully in implementing interoperable building automation systems, the approaches to interoperability are vastly different.

For connection security, the U.S. government has mandated that bases remove their building controls infrastructure to a “dark fiber” segmented network. Network hardware is monitored by an InterMapper server that resides on the segmented network. The InterMapper server monitors network data such as device downtime and available bandwidth. Electric-power-meter data from the Sensus devices operate on a 900MHz radio spectrum. McKenney’s created a custom Niagara application that collects the data from specified points and writes to a .log file that is monitored by Splunk.

Collect

Sensus meter data is collected in a SQL server then passed to the Splunk indexer. HVAC data is collected in 15-minute increments and power-meter data is collected continuously by Sensus. The indexer also collects information from flat files that can be manually input, as well as log files from the Niagara AX system and InterMapper server.

Splunk performs real-time and historical search, reports and statistical analysis. The product can index structured or unstructured, textual, machine-generated data. Search and analytics operations are specified using their Search Processing Language. Originally based upon Unix Piping and SQL, its scope includes data searching, filtering, modification, manipulation, insertion and deletion. Eglin data is being archived via Splunk Enterprise with a three-year data-retention policy.

Splunk runs on a dedicated server on Eglin’s private network and all site data feeds into and is collected by a Splunk indexer. A Splunk search head resides on another server and allows users to access and create custom searches and reports.

Learn

By correlating both historical and real time energy utilization and pricing data with occupancy and environmental data from the HVAC, the base identified significant opportunities for load shedding, such as times it can shut off select HVAC systems during high energy cost periods.

Splunk is also being used to analyze the data. Data is analyzed continuously and on-demand as requested by the users. Initial functionality is focused on utility visualization and cost allocation. Insights are being gained relative to structure-performance baselines. For example, what is the efficiency of a wood frame versus concrete block buildings? Subsequent phases will incorporate predictive analytics and automated, cost-management routines.

Do

Leroy’s team built an energy management application that provides dashboards to help Eglin’s maintenance staff assess building performance and energy efficiency, generate automated Air Force and DoD energy usage reports, compare current energy usage with historical data, and enable the deployment of load shedding and load shifting strategies to take advantage of favorable electric rates. All of this leads to more precise building management, lower costs and improved service, health and safety.

Lower Consumables Cost

The U.S. Department of Energy’s Federal Energy Management Program (FEMP) chose Eglin as the recipient of a 2015 energy and water conservation award. The award recognizes Eglin’s innovative approach for combining advanced technologies and common sense to saving critical energy resources and reducing utility costs for the base. By integrating direct digital controls, facility meters, and comprehensive energy analyses, the project saved 181-billion BTUs of electricity and natural gas across 131 buildings, valued at $3.4M.

Higher Quality Service

The technology also has the ability to improve the quality of service. For example, if boilers, chillers, variable air-volume systems or other building maintenance components are not performing optimally, the building service department can proactively fix these hardware issues, avoiding even more expensive service calls.

Improved Health and Safety

Finally, from a safety perspective, one aspect is that many of the meters being read and recorded are located in mid-field equipment buildings, which require personnel on active runways to diagnose problems and read data. Clearly, this is no longer necessary. If I was somebody who had to cross active runways populated with high performance military jets, I’d be thanking Leroy and his crew.

Leroy is retiring from McKenney’s this year and they’re throwing him a great going away party, but he, as many of us, sees the untapped potential to create precision buildings around the world. If you’re interested in learning more as a electrical, computer, or mechanical engineer, consider enrolling in a new online class we call Precision—the Class. It will take you thru the fundamental technologies, some you might be familiar with, others might be new to you. But that’s not all. The class goes on to teach you over fourteen case studies that cross agriculture, power, construction, transportation, water, and healthcare.

About the Author

Dr. Chou started his career in Silicon Valley at one of the first Kleiner-Perkins startups, Tandem Computers. Since then he’s been lucky enough to be a part of some successful and not so successful startups and today serves as the Chairman of the Alchemist Accelerator. He has also personally invested in a select group of startups.

Dr. Chou started his career in Silicon Valley at one of the first Kleiner-Perkins startups, Tandem Computers. Since then he’s been lucky enough to be a part of some successful and not so successful startups and today serves as the Chairman of the Alchemist Accelerator. He has also personally invested in a select group of startups.

Timothy has also worked at some large companies including Oracle Corporation, where he was President of Oracle On Demand. At the time he was one of only three people to ever hold the title of President at Oracle. Today he consults for Fortune 100 companies and currently serves as a member of the board of directors of two public companies, Blackbaud and Teradata.

In parallel with his commercial career he has taught at Stanford University for over thirty years. For fifteen years he taught introductory computer architecture and only took a leave of absence because he had to fly to Bali for a sales kickoff and get back within 36 hours to teach class. After leaving Oracle he started Stanford’s first class on cloud computing, cs309a.stanford.edu. He has lectured at over twenty-five universities around the world and delivered keynote speeches on six continents. If you’re interested in learning more register for the online class at www.precisionstory.com/class.